PRODUCTS - Leather cutting

Nesting Automatico

WaveNest: automatic nesting system for textile supplied in sheet or on rolls.

The application determines best strategy to optimize the textile cutting giving maximum efficiency by using different algorithms which administrate the markers and reduce the waste.

The application determines best strategy to optimize the textile cutting giving maximum efficiency by using different algorithms which administrate the markers and reduce the waste.

The efficiency depends basically on the shapes, on the allowed rotations (none, 180° only, 90° steps, free, etc.) and on the gap required between the parts and between each part and the edge of the material.

All the operations related to the nesting can be made with our program and includes:

• loading one or more shapes to be placed ;

• assign the required quantity;

• assign the material to be used ;

• calculate the nesting ;

• save the program for the cutting machine

• get a report of the estimated material consumption and cost.

Orders and material sizes can be imported from external databases or just quickly typed in. WaveNest can optimize the consumption of material of upholstery shapes on fabric rolls.

FOR TECHNICAL MATERIAL

It is also possible to optimize the consumption material in case of large parts like sails or parachutes on rolls or gaskets on sheets of synthetic material by using a WaveNest special application called TechNest.

It is also possible to optimize the consumption material in case of large parts like sails or parachutes on rolls or gaskets on sheets of synthetic material by using a WaveNest special application called TechNest.

TechNest Suite was developed to comply with the different patterns forms with different cutting material. The software contains several functions to speed up the creation of new patterns and which are easy to use and allow to reduce creation time.

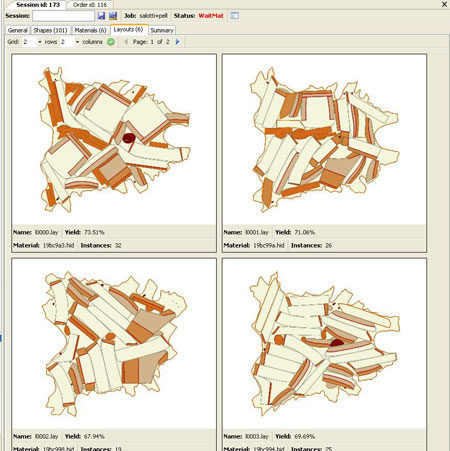

FOR LEATHER - (LuxuryNest: automatic nesting system for leather. )

Optimizing the yield is a topic of great interest when we talk about leather cutting and LuxuryNest software LuxuryNest offers many advantages:

Optimizing the yield is a topic of great interest when we talk about leather cutting and LuxuryNest software LuxuryNest offers many advantages:

• Reduce manual intervention;

• Combine automatic and interactive optimization;

• Intelligent interaction with the various quality areas (nesting is done automatically, respecting the previously indicated quality zones of leather and patterns);

• Increase your efficiency and productivity;

• More material across your table in less time with improved results;

• Visualization of the yield of hide before cutting;

• Visualization of the final layout on screen and projected simultaneously on the material laid on the cutting table;

• Access individual nest or total job information at any time making real-time comparisons and cost optimization easily possible;

• Keep your production under control at any time